Miller Electric MPS-20FT User Manual Page 5

- Page / 8

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

5

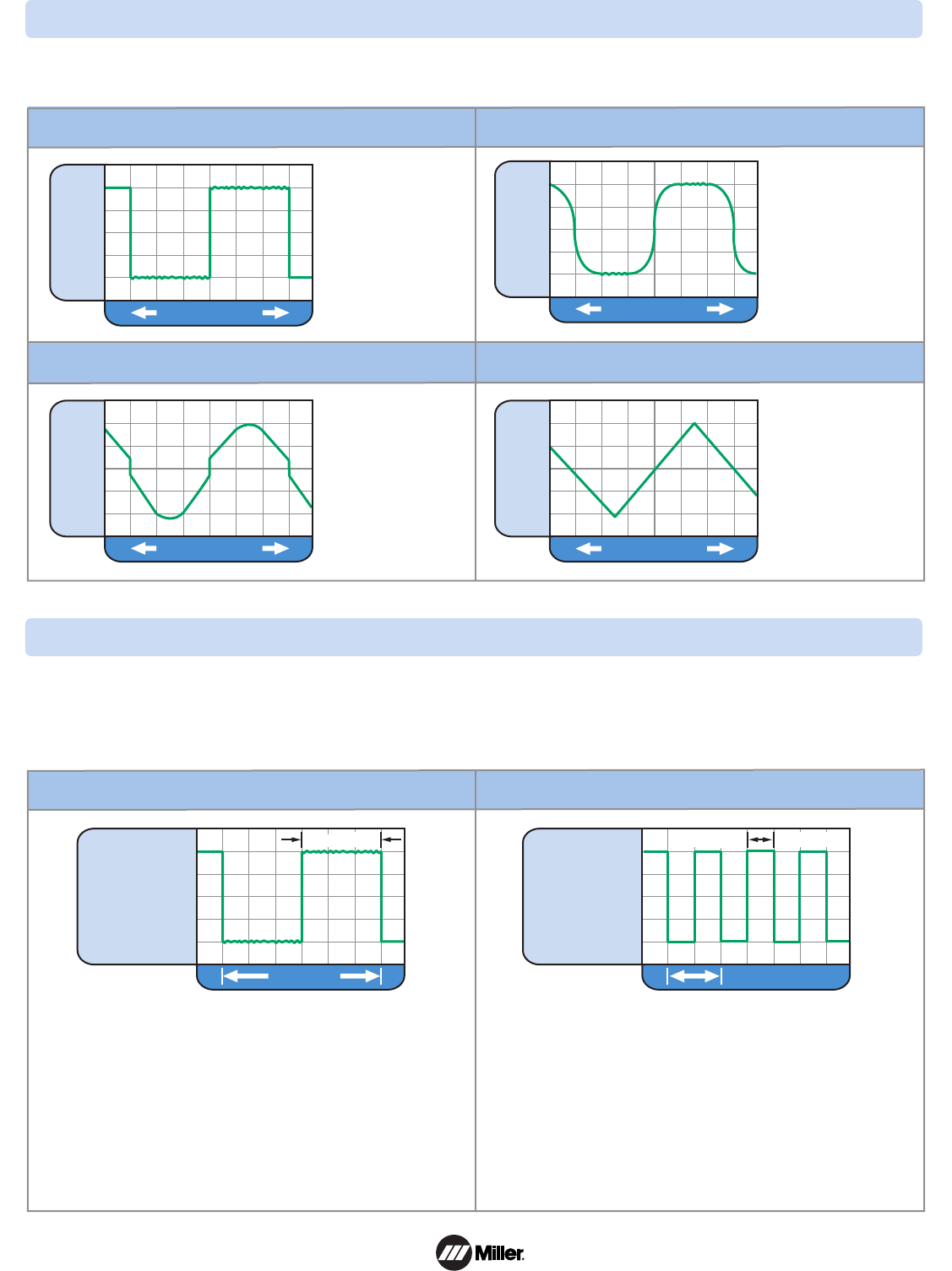

SINEWAVE TRIANGULAR WAVE

ADVANCED SQUAREWAVE SOFT SQUAREWAVE

AC Waveform Selection

Select from four different AC waveforms to optimize the arc characteristic for your application. Choose from:

High Speed DC TIG-Pulse Controls

• PPS Pulses per second (Hz): DC = 0.1 – 5,000 PPS / AC = 0.1 – 500 PPS

• % ON – % Peak Time: 5 - 95% (Controls the amount of time during each pulse cycle at the PEAK amperage.)

• Background Amps: 5 – 99% (Sets the low-pulse amperage value as a % of the Peak Amps.)

Fast transitions for

responsive and

dynamic arc.

0

Amps

Time (1 AC Cycle)

Square transitions

eliminate the need for

continuous HF, while

the sinewave peaks

soften the arc.

0

Amps

Unconventional wave

provides the punch of

the peak amperage,

while reducing overall

heat input. Quick puddle

formation reduces weld

time — limiting

heat

input and reducing

weld

distortion, especially

on thin materials.

0

Amps

All the benefits of

advanced square,

fine tuned to provide

a smooth, soft arc

with maximum

puddle control and

good wetting action.

0

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

Amps

CONVENTIONAL PULSED TIG HIGH SPEED PULSED TIG

Typically from 1 to 10 PPS. Provides a heating and cooling effect

on the weld puddle and can reduce distortion by lowering the

average amperage. This heating and cooling effect also produces a

distinct ripple pattern in the weld bead. The relationship between

pulse frequency and travel speed determines the distance between

the ripples. Slow pulsing can also be coordinated with filler metal

addition and can increase overall control of the weld puddle.

Peak

Amps

Background

Amps

(% of Peak)

In excess of 40 PPS, Pulsed TIG becomes more audible than visible —

causing increased puddle agitation for a better as-welded microstructure.

Pulsing the weld current at high speeds — between a high Peak and a

low Background amperage — can also constrict and focus the arc.

This results in maximum arc stability, increased penetration and

increased travel speeds (Common Range: 100 – 500 PPS).

The Arc-Sharpening effects of high speed pulsing are expanded to new

dimensions. The ability to pulse at 5,000 PPS further enhances arc

stability and concentration potential — which is extremely beneficial to

automation where maximum travel speeds are required.

Time (1 AC Cycle)

Time (1 AC Cycle)

Time (1 AC Cycle)

Pulse Cycle

Peak Time %

Peak

Amps

Background

Amps

(% of Peak)

Pulse Cycle

Peak Time %

AC Waveshape Controls (Continued)

Pulse TIG Controls

(80 pages)

(80 pages) (80 pages)

(80 pages)

Comments to this Manuals