Miller Electric Big 40 WG Owner's Manual Page 42

- Page / 80

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

OM-4405 Page 38

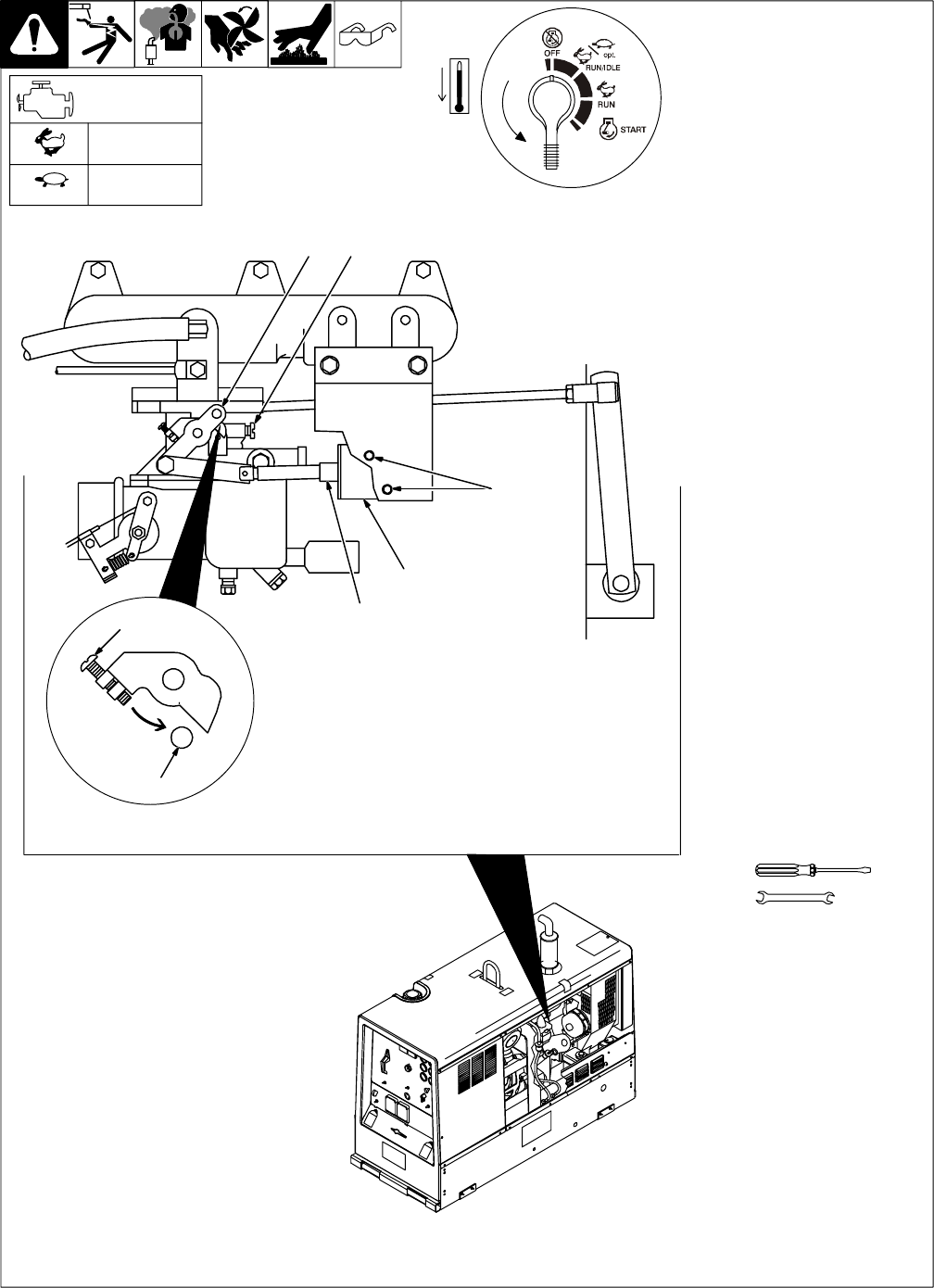

8-6. Adjusting Engine Idle Speed

802 731 / Ref. 115 155-A

Stop engine and let cool.

Engine idle speed is factory set and

normally should not require adjust-

ment. After tuning engine, check

engine speed with tachometer or

frequency meter. See table for

proper no load speed. If necessary,

adjust idle speed as follows:

Start engine and run until warm.

On CC Models, place Stick/TIG

switch in Stick position.

On CC/CV models, turn Process/

Contactor switch to Stick – Elec-

trode Hot position.

1 Solenoid Bracket Screws

2 Throttle Arm

3 Idle Speed Screw

4 Throttle Stop

Loosen bracket screws and move

arm so screw touches stop. Do not

release arm. Turn idle speed screw

to obtain 550 rpm.

5 Idle Mixture Screw

Turn mixture screw counterclock-

wise until engine falters, then turn

screw clockwise until engine runs

smoothly.

Turn idle speed screw to obtain

1250 rpm.

6 Solenoid

7 Plunger

Slide solenoid inside bracket so

plunger bottoms in solenoid. If nec-

essary, shim solenoid/bracket to

prevent linkage from binding. Do

not readjust idle speed screw when

adjusting solenoid.

Tighten bracket screws. Release

throttle arm. Recheck idle speed

and readjust if necessary.

Stop engine.

Close door.

Tools Needed:

1

2

3

4

5

6

7

1/4 in

1850 rpm max

(61.6 Hz)

1250 rpm

(41.6 Hz)

Engine Speed

(No Load)

- Big 40 WG 1

- From Miller to You 2

- TABLE OF CONTENTS 3

- 1-1. Symbol Usage 5

- 1-2. Arc Welding Hazards 5

- 1-3. Engine Hazards 6

- 1-6. EMF Information 8

- UTILISATION 9

- LE CARBURANT MOTEUR peut pro 10

- UNE REMORQUE QUI BASCULE peut 11

- SECTION 2 – DEFINITIONS 13

- SECTION 3 – SPECIFICATIONS 13

- Dimensions 14

- 202 655 / 202 656 / 202 654 15

- 3-5. Fuel Consumption 16

- 3-7. AC Auxiliary Power Curve 17

- SECTION 4 – INSTALLATION 18

- 4-4. Installing Exhaust Pipe 19

- 4-6. Connecting The Battery 21

- 4-7. Engine Prestart Checks 22

- S-0007-E– 23

- 201 841 / 802 729 26

- OM-4405 Page 25 29

- 201 579 / 802 729 30

- 0774 / Ref. 201 579 / 802 730 33

- 191 624-A 34

- Ref. 197 399 / 802 332-E 35

- 91 92 93 35

- 8-1. Maintenance Label 37

- 802 729 / Ref. 201 841 39

- 8-4. Servicing Air Cleaner 40

- RPM (Hz) 41

- 802 731 / Ref. 115 155-A 42

- 802 780 / Ref. 115 155-A 43

- 802 731 / Ref. 801 434 44

- 8-9. Overload Protection 45

- Ref. 201 841 46

- 8-11. Troubleshooting 47

- B. Welding – CC/CV Models 48

- C. Standard Auxiliary Power 49

- E. Engine 49

- Trouble Remedy 50

- OM-4405 Page 47 51

- OM-4405 Page 48 52

- OM-4405 Page 49 53

- OM-4405 Page 50 54

- OM-4405 Page 51 55

- 10-1. Selecting Equipment 56

- ST-800 576-B 57

- Ref. ST-800 396-A / S-0625 60

- S-0405-A 61

- OM-4405 Page 59 63

- SECTION 11 – PARTS LIST 64

- OM-4405 Page 62 66

- OM-4405 Page 63 67

- 802 551-A 68

- OM-4405 Page 65 69

- OM-4405 Page 67 71

- Hardware is common and 72

- OM-4405 Page 69 73

- OM-4405 Page 71 75

- OM-4405 Page 73 77

- Effective January 1, 2000 79

- For Service 80

- Owner’s Record 80

(40 pages)

(40 pages) (80 pages)

(80 pages)

Comments to this Manuals