Miller Electric A1D-4RV Specifications Page 13

- Page / 22

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

B.

One-Piece

Drive

Roll

(Figure

4-2

and

4-3)

IMPORTANT:

One-piece

drive

rolls

are

of

the

double

usage

type.

When

the

grooves

become

worn,

reverse

each

drive

roll,

locating

the

unused

groove

in

position

to

feed

the

wire.

1.

Loosen

pressure

adjustment

knobs

and

pivot

them

free

of

the

covers.

2.

Pivot

gear

covers

away

to

expose

pressure

gears.

3.

Loosen

and

remove

the

three

securing

screws

on

each

gear.

4.

Slide

a

drive

roll

onto

each

drive

gear

and

pressure

gear,

align

holes,

and

secure

with

screws.

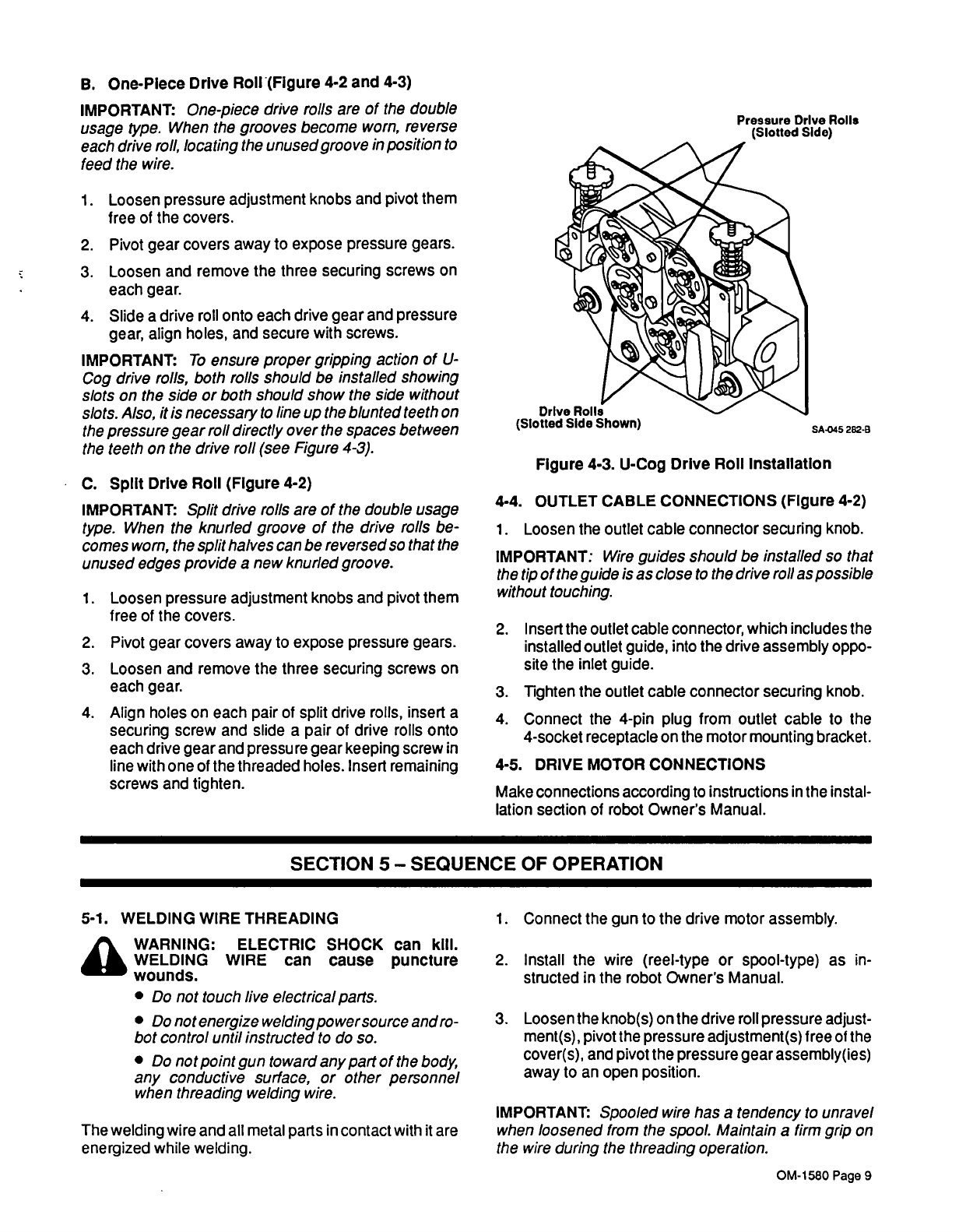

IMPORTANT:

To

ensure

proper

gripping

action

of

U-

Cog

drive

rolls,

both

rolls

should

be

installed

showing

slots

on

the

side

or

both

should

show

the

side

without

slots.

Also,

it

is

necessary

to

ilne

up

the

blunted

teeth

on

the

pressure

gear

roll

directly

over

the

spaces

between

the

teeth

on

the

drive

roll

(see

Rgure

4-3).

C.

Split

DrIve

Roll

(Figure

4-2)

IMPORTANT:

Split

drive

rolls

are

of

the

double

usage

type.

When

the

knurled

groove

of

the

drive

rolls

be

comes

worn,

the

split

halves

can

be

reversed

so

that

the

unused

edges

provide

a

new

knurled

groove.

1.

Loosen

pressure

adjustment

knobs

and

pivot

them

free

of

the

covers.

2.

Pivot

gear

covers

away

to

expose

pressure

gears.

3.

Loosen

and

remove

the

three

securing

screws

on

each

gear.

4.

Align

holes

on

each

pair

of

split

drive

rolls,

insert

a

securing

screw

and

slide

a

pair

of

drive

rolls

onto

each

drive

gear

and

pressure

gear

keeping

screw

in

line

with

one

of

the

threaded

holes.

Insert

remaining

screws

and

tighten.

Figure

4-3.

U-Cog

Drive

Roll

InstallatIon

4-4.

OUTLET

CABLE

CONNECTIONS

(Figure

4-2)

1.

Loosen

the

outlet

cable

connector

securing

knob.

IMPORTANT:

Wire

guides

should

be

installed

so

that

the

tip

of

the

guide

is

as

close

to

the

drive

roll

as

possible

without

touching.

2.

Insert

the

outlet

cable

connector,

which

includes

the

installed

outlet

guide,

into

the

drive

assembly

oppo

site

the

inlet

guide.

3.

Tighten

the

outlet

cable

connector

securing

knob.

4.

Connect

the

4-pin

plug

from

outlet

cable

to

the

4-socket

receptacle

on

the

motor

mounting

bracket.

4-5.

DRIVE

MOTOR

CONNECTIONS

Make

connections

according

to

instructions

in

the

instal

lation

section

of

robot

Owners

Manual.

SECTION

5

SEQUENCE

OF

OPERATION

5-1.

WELDING

WIRE

THREADING

a

WARNING:

ELECTRIC

SHOCK

can

kill.

WELDING

WIRE

can

cause

puncture

wounds.

Do

not

touch

live

electrical

parts.

Do

not

energize

welding

po

wersource

andro

bot

control

until

instructed

to

do

so.

Do

not

point

gun

to

ward

any

part

of

the

body,

any

conductive

surface,

or

other

personnel

when

threading

welding

wire.

The

welding

wire

and

all

metal

parts

in

contact

with

it

are

energized

while

welding.

1.

Connect

the

gun

to

the

drive

motor

assembly.

2.

Install

the

wire

(reel-type

or

spool-type)

as

in

structed

in

the

robot

Owners

Manual.

3.

Loosen

the

knob(s)

on

the

drive

roll

pressure

ad

just

ment(s),

pivot

the

pressure

adjustment(s)

free

of

the

cover(s),

and

pivot

the

pressure

gear

assembly(ies)

away

to

an

open

position.

IMPORTANT:

Spooled

wire

has

a

tendency

to

unravel

when

loosened

from

the

spool.

Maintain

a

firm

grip

on

the

wire

during

the

threading

operation.

Pressure

Drive

Roiis

(Siottod

Side)

Drive

Roiis

(Slotted

Side

Shown)

SA-045

282~B

OM-1580

Page

9

- IMPORTANt: 1

- WARRANTY 2

- Transportation 3

- Replacement 3

- Assembly 4

- Identifying 6

- Connections 7

- Grounding 8

- Cutting. 8

- Society 9

- Capacity 11

- Securing 12

- IMPORTANT: 15

- ELECTRICAL 17

- DIAGRAMS 17

- 3~sIncIuded 19

- TERMINAL 20

- Description 21

(40 pages)

(40 pages) (32 pages)

(32 pages)

Comments to this Manuals