Miller Electric MPS-10T Specifications Page 19

- Page / 24

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

OM-235 369 Page 17

4-3. Maintenance And Storage

Replace damaged or dirty filter. Do not wash filter, clean with compressed air, or reuse

dirty filter.

Never use solvents or abrasive cleaning solutions to clean the helmet cooling system.

Keep water and other fluids out of blower assembly.

Replace shroud after 50 washings. Shroud loses its fire retardant properties with re-

peated washing.

For best performance clean the equipment after each use. Use a soft cloth dampened with a mild soap

and water solution to wipe all external surfaces clean. Allow to air dry.

Product usage, workplace contamination levels, and other factors affect the life of the filter. Replace

filter if air flow is reduced due to a dirty filter (see Section 3-6).

Inspect flexible tube and replace if damaged or if inside of tube is extremely dirty.

If the helmet cooling system will not be used for an extended period, remove the filter and battery and

store in a clean, dry place free of solvent-based vapors them and at a temperature of −4° to 86° F (−20°

to 30° C). Charge battery to 50 percent capacity before storage.

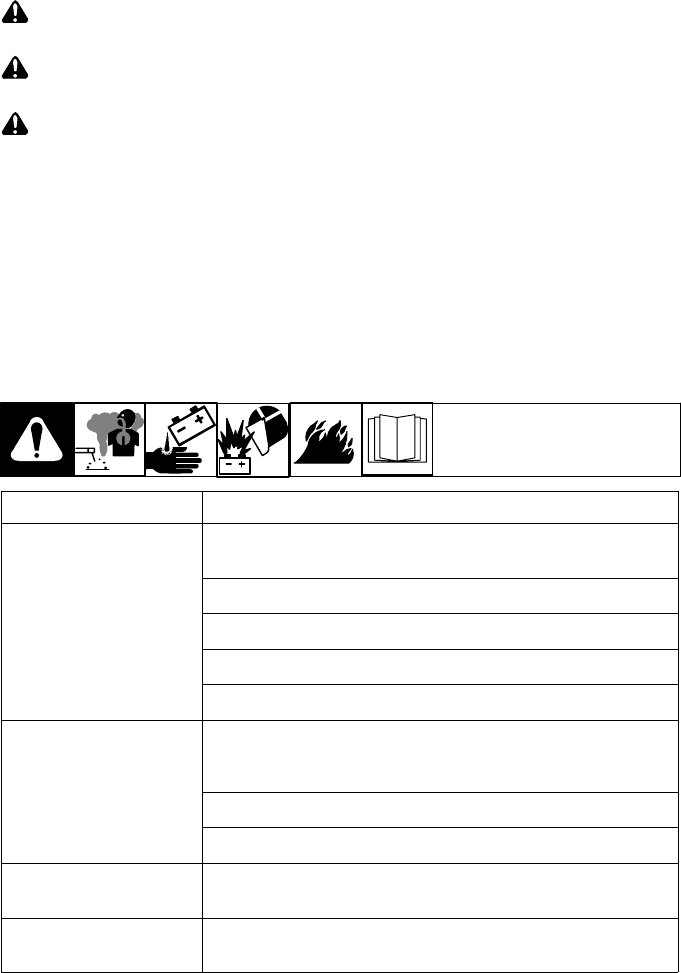

4-4. Helmet Cooling System Troubleshooting

Trouble Remedy

Blower assembly does not

supply air to helmet.

Press Power button.

Dead battery; recharge battery (see Section 3-5).

Remove tape from battery terminals (new battery only).

Verify battery contacts are clean and free of obstructions.

Remove blockage from blower assembly outlet and tube.

Blower assembly runs for

short time even though

battery is fully charged.

Be sure battery is properly connected to battery charger.

Replace battery.

Replace charger.

Battery Level red light is

on or flashing.

Charge or replace the battery. The blower assembly will operate

for about 15 minutes after the light starts flashing.

Blower assembly is

pulsing on and off.

Charge or replace the battery. The blower assembly will operate

for about 15 minutes after the light starts flashing.

- Auto-Darkening Helmets 1

- Model: CoolBandtIntegrated 1

- Headgear Cooling System 1

- TABLE OF CONTENTS 2

- READ BEFORE USING 3

- 1-1. Symbol Usage 3

- 1-2. Hazards 3

- 2-1. Symbol Usage 5

- 2-2. Hazards 5

- READ INSTRUCTIONS 6

- 3-2. Installing Headgear 9

- Work like a Pro! 10

- 3-4. Charging The Battery 11

- . To better show components 12

- . Remove tape from battery 12

- . See Section 3-10 to operate 12

- . Light pressure on Power 14

- . See Section 4 (Miller hel 15

- SECTION 4 − MAINTENANCE 17

- 4-3. Maintenance And Storage 19

- SECTION 5 − PARTS LIST 21

- SECTION 6 − LIMITED WARRANTY 22

- Miller Electric Mfg. Co 24

(40 pages)

(40 pages) (36 pages)

(36 pages)

Comments to this Manuals